• Maintenance-free.

• Increases efficiency and decreases maintenance of filter separators.

• Permanently lubricated dual race swivel joints.

• Triple-sealed swivel joints specially designed for submerged service.

• Refineries, Aviation Fuel Stations

Available materials of construction : SS, Aluminium

3”, 4”, 8”, 10”12”, 20”, 24”

• HPCL (Hindustan Petroleum Corporation Limited)

• BPCL (Bharat Petroleum Corporation Limited)

• IOCL (Indian Oil Corporation Limited)

• N. R. Patel & Co.For IOCL, Trivandrum Airport (Aviation Fuel station)

• TankTech Asia Private Limited , Chennai

• Degremount Ltd. For Astana WTP & STP, Kazakhstan

• Tech Mech Constructions, Guwahati, Assam

• SUPREME PETROCHEM LTD

• DOVER India Pvt. Ltd. OPW Fluid Transfer Division Navi Mumbai

• CV. Mediterania INDONESIA

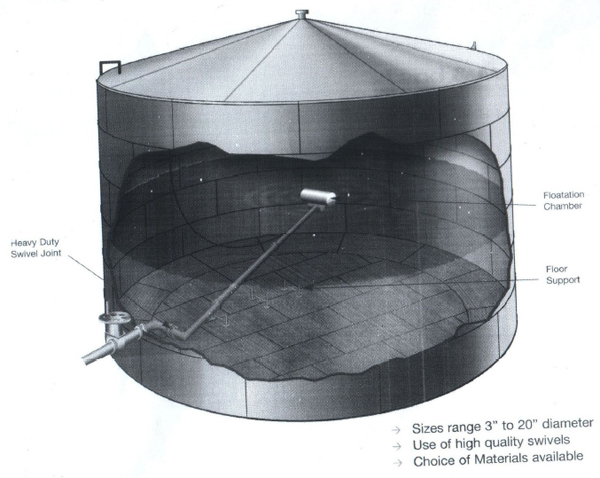

A Floating Suction unit is designed to enable product to be drawn off the tank

either from the top surface of the liquid or at a predetermined depth below the

surface of the liquid, This means that after filling, the tank can be used

immediately as any unwanted particles like dirt or other contaminates even water

remain in the tank.

Floating Suction units are of various designs however the essential features

include rigid pipe, custom designed pressure tested floats and swivel joints

manufactured by us.

Steelfab Engineering can provide the prefabricated Floating suction unit

complete with an installation manual for final assembly and installation at site by

the customer. Alternatively, Steelfab Engineering can provide assistance for

installation at an extra cost.

• To ease installation, all component parts of the Floating suction unit can

pass through a standard tank shell manhole.

• The arm cannot lock in a vertical position. It is very important that the tank diameter

is less than the height - a stainless steel restraining wire rope is

attached to the upper end of the pipe.

• The Floating Suction unit is installed in a fixed position, air is not trapped in the

arms during tank filling - at the highest point a hole is drilled in the pipe to allow air to

escape.

• Long life and trouble free operation is achieved due to the use of swivel

joints specifically designed for submerged service.

• At low level, the Floating Suction unit is rested on supports - this avoids

the pipe work resting on any sediment at the bottom of the tank.

• The Floating Chambers are designed in such way that if one is punctured

the remaining one can keep the unit Floating.

• The Floating Suction unit can be installed and operated in a fixed roof,

external floating root and an internal floating roof tank.

• As the product is always taken from the top surface and is less likely to be

contaminated, this decreases the maintenance of filters in the draw - off

lines.

• Taking into consideration of the specifications of the stored product and

operational requirement of the tank, the Floating Suction units are

designed, hence the required purpose is achieved satisfactorily.

Floating Suction Assembly consists of following components

• Swivel joint - It is associated with elbow & connection flange.

• Suction Pipe - It is of length suitable to transport.

• Float Assly - It consists of floats ( Qty depends on the buoyancy

required)

• Baffle plate assly. It is always assembled with end piece of suction

pipe.

• Hardware & gaskets - Normally packed in separate box.

We provide General arrangement drawing of the Floating suction unit along with installation drawings component - wise at the time of dispatch of each unit.

Please follow below mentioned procedure to assemble the Floating suction assembly

• Open the packing & check all items as per packing slip.

• Take all the items inside the tank.

• Lay the items as per General Arrangement drawing.

• Start assembling as per the drawing. ( Serial numbers of the assembly

components are marked on the individual components for easy

assembly).

• For hydro testing the Floating Suction unit, remove the end plate of the

baffle plate assembly & fix the suitable blind flange ( in Customer's

Scope). Drawing for blind flange (for hydro testing only) will be provided.

• Assemble the floats as per the drawing and place the floats in such

position that it will float as the product enters into the tank.

• Floating Suction unit is ready for use